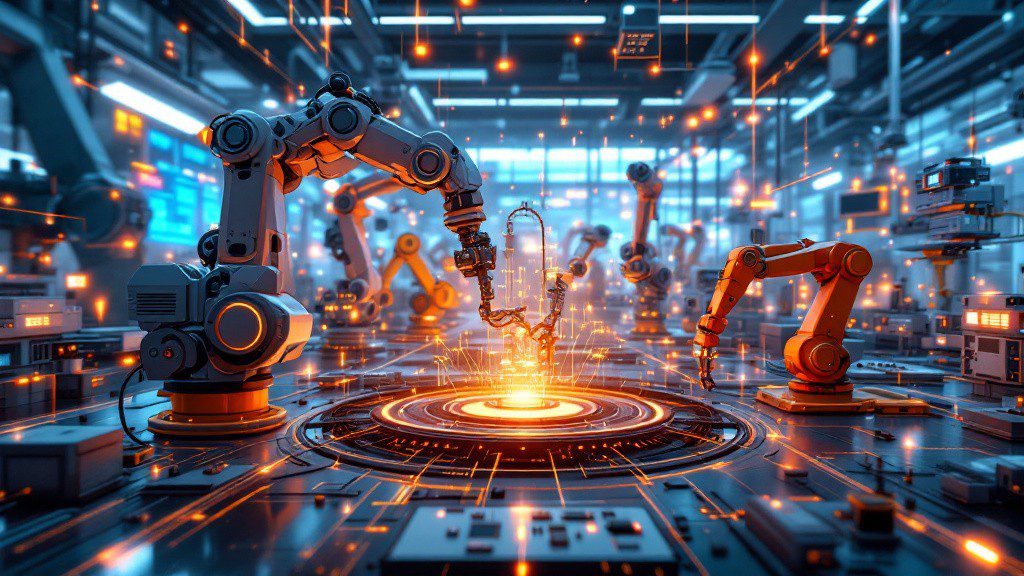

NVIDIA’s groundbreaking Omniverse platform and Mega Omniverse Blueprint are revolutionising industrial AI through advanced digital twin technology, enabling manufacturers to simulate and optimise robot fleets in virtual industrial environments before real-world implementation.

This innovative platform represents a significant advancement in industrial automation, allowing companies to develop, test, and optimise AI-powered robot systems at an unprecedented scale. By creating detailed virtual replicas of physical facilities, manufacturers can now simulate complex operations without disrupting existing production processes, leading to substantial cost savings and efficiency improvements.

According to McKinsey research, digital twin technology has gained remarkable traction in advanced industries, with approximately 75% of companies adopting these solutions as a strategic competitive advantage. The technology’s ability to enable risk-free testing and refinement of automated systems in virtual environments has made it an essential tool for modern manufacturing.

The Mega Omniverse Blueprint’s integration capabilities stand as a cornerstone of its effectiveness. The platform seamlessly incorporates NVIDIA’s cutting-edge technologies, including OpenUSD, NVIDIA RTX rendering, and AI-driven solutions like NVIDIA Isaac ROS.

This comprehensive integration facilitates the simulation of extensive sensor data from multiple machines, enabling thorough testing of robots across diverse scenarios within the digital twin environment.

Major industry players have already embraced this transformative technology. Notable organisations such as Accenture, Foxconn, and KION Group AG are actively utilising the Mega Omniverse Blueprint to enhance their industrial operations.

A prime example is KION Group’s collaboration with Accenture and NVIDIA, which has resulted in significant improvements in warehouse automation and supply chain optimisation.

The impact of digital twin technology extends beyond current applications, addressing critical industry challenges such as labour shortages and escalating operational costs.

As manufacturing and logistics sectors continue to evolve, digital twins are positioned to play an increasingly vital role in driving industrial innovation and efficiency.

The technology’s ability to support continuous development, testing, and deployment of software-defined facilities marks a significant shift in industrial operations.

This approach not only reduces implementation costs but also minimises risks associated with deploying new automated systems.

As industry adoption continues to grow, NVIDIA’s Omniverse platform and Mega Omniverse Blueprint are setting new standards for industrial AI implementation.

The technology’s potential to enhance operational efficiency and scalability positions it as a crucial driver of future manufacturing innovation.

Source: NVIDIA Blog